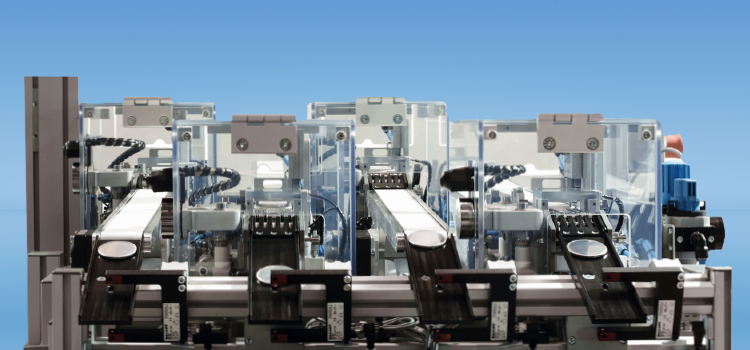

Our "4/2 Weight Check"

The "4/2 Weight Check" is our weighing equipment of the highest quality.

For blanks and coins from Ø 25 to 42 mm and 10 g to 100 g.

The highlight of this machine is the throughput of 200 pcs. per minute with a repeatability of +/- 0.002 g. A total of four parallel (but independently) working weighing lines allow for this performance.

Should this not meet your needs, it is possible to expand up to six lines and thus weigh 300 pieces/minute. With this accuracy, our weighing machine is the fastest available system on the market.

Weighing as quality control

The weight of a coin/blank is more than just a parameter in the production, it is a legally guaranteed minimum weight and this ensures the material value.

The target weight of an optimal coin/blank is thus (a few mg) just above the nominal value. Below this, there is the immediate melting of the blank. If this is significantly exceeded, more material will be needed as required.

The 100% precise & accurate weight control in the production process is the only way to optimize the production – so that the objective weight of the coin/blank is followed correctly.

In addition, the weighing offers the possibility to divide the coins/blanks in weight classes and so prepare them for a possible material recovery.

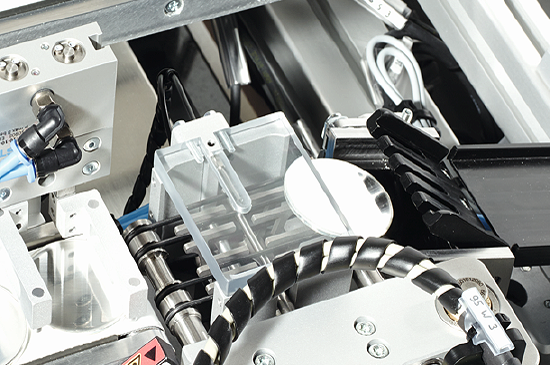

Discharge of rejects

Each weighing line has a special valve system that ensures the discharge of “reject” blanks/coins immediately after weighing. “Reject” in this case means that the desired weight of the respective object was under or over target weight- and thus through discharging the objects are distinguished and ejected separately.

Only when the “reject” blank/coin has triggered a light barrier in the discharge chute, the next blank/coin is weighed. Thus we ensure that no blanks/coins are further processed if the weight does not comply.

It is a good feeling to be able to trust that all products take their right path!

Ultra Accurate Precision-weighing (+/- 0,0002 g)

Our “UP-Weight Check” is a completely new approach for small products from 1 to 50g (with any shape) – because less is more!

No matter what shape the product that is to be weighed has – as long as it can be laid down, we can weigh it – and we can do it 15 to 20 times per minute and lane with a repeated precision of +/- 0.0002g! We have reached our goal of achieving lab precision in an industrial setting with this new concept.

You know the requirement:

tiny products that can only be measured by a laboratory scale.

The slightest whiff of air influences the measurement, which is why this scale is completely enclosed. Which means open the door, close the door – make the measurement – and then open the door again in order to remove the product and continue in the process.

We have a more practical solution for this complicated and sensitive process:

An automatic feeding creates the right separation and positioning of your product on the scale. The following weighing process happens with a resolution of 0.0001g and with a repeated precision of +/- 0.0002g. If the measurement shows that the product does not have the desired weight, it will automatically be displaced into the reject area and will not move on to the following production process.

Economa.at – engineering that works

At Economa, we stand for a high-quality approach in the field of apparatus & special machine construction – so call us, send us a message or visit our company at economa.at